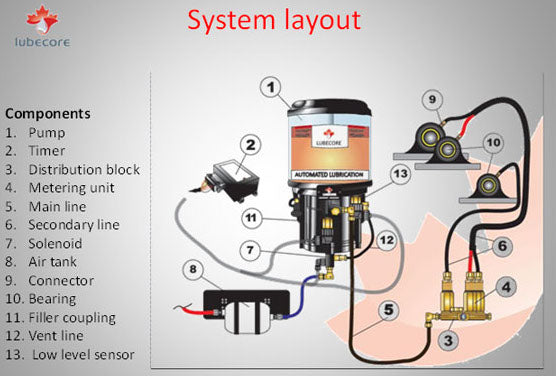

Lubecore automatic greasing systems may seem complicated, but they are fairly simplistic. Basic components of an automatic lubrication system include a pump, controller, tubing or hose, metering devices, and fittings to connect to the specific lubrication points.

Pump

The pump provides flow of oil or grease under pressure to actuate the metering device(s) that lead to the specific grease points. Lubecore offers three families of pumps for virtually any type of equipment. The selection is based upon the types of grease required (e.g., EP0 or EP2), the available power source (pneumatic, electric, or hydraulic), and numbers of grease points plumbed.

Controller

A controller runs a schedule to dispense lubrication. Most Lubecore pumps have a built-in controller that is fully potted in silicone, protecting the electronics from water, dust, dirt, etc. and set with a magnet (not a traditional switch) further protecting the components from outside environmental factors.

Tubing and Fittings

The correct tubing must be strong enough to handle the pressure developed in the system and heavy-duty enough to allow for protection in high-wear or movement locations. Lubecore uses premium nylon lines and high pressure Korilla lines. The lines terminate in non-corrosive fittings designed for each grease point.

Metering

Each point requires differing amounts of grease. Lubecore uses specific injectors or manifolds to meter out exactly what each point needs without over or under-greasing any one point.